Introduction

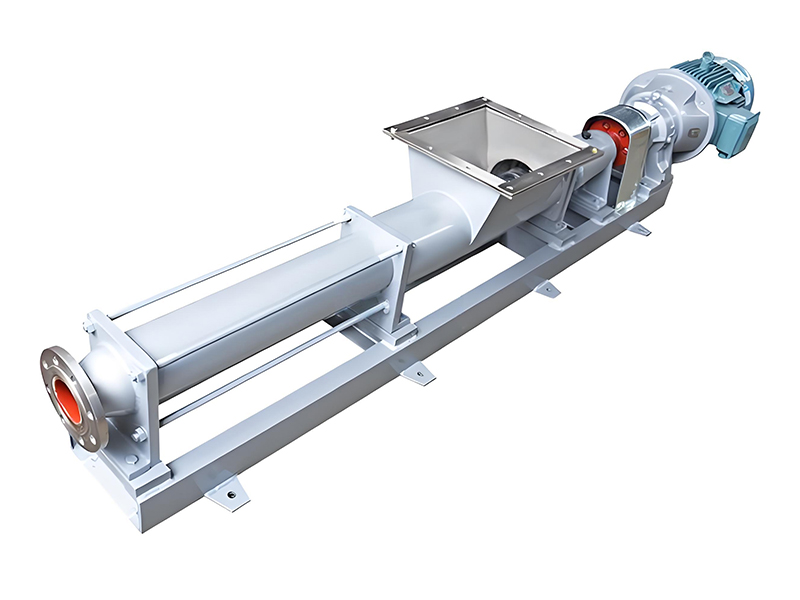

The G-Type Movable Single-Screw Pump is a positive displacement pump renowned for its ability to handle high-viscosity, abrasive, and shear-sensitive fluids. Its design allows for smooth, continuous, and pulsation-free flow, making it ideal for various industrial applications.

Flow Rate: 0.8 – 150 m³/h

Maximum Head: Up to 120 meters

Maximum Pressure: 1.2 MPa

Maximum Viscosity: 2.7 × 10⁵ cSt

Temperature Range: Up to 150°C

Materials:

Casing: Cast Iron / Stainless Steel

Screw: SS201 / SS304 / SS316

Stator: NBR / Silicon Gel

Seal Type: Packing Seal

Drive Options: Electric Motor or Diesel Engine

Mounting: Horizontal

Self-Priming Capability: Yes, up to 3 meters

The G-Type pump operates using a single helical screw that rotates within a stator. As the screw turns, it moves the fluid along the pump's axis, creating a sealed cavity that ensures a continuous and uniform flow. This design minimizes pulsations and shear, making it suitable for delicate or abrasive materials.

The G-Type Movable Single-Screw Pump is versatile and finds applications in various industries, including:

Chemical Processing: Handling viscous chemicals and slurries.

Food & Beverage: Pumping pastes, sauces, and syrups.

Wastewater Treatment: Transporting sludge and other thick liquids.

Oil & Gas: Moving crude oil, emulsions, and other heavy fluids.

Pharmaceuticals: Processing creams, ointments, and other sensitive substances.

High Viscosity Handling: Capable of pumping fluids with viscosities up to 2.7 × 10⁵ cSt.

Pulsation-Free Flow: Ensures smooth and consistent delivery.

Self-Priming: Can operate without the need for external priming systems.

Durability: Constructed with high-quality materials for extended service life.

Versatility: Suitable for a wide range of applications across various industries.

Installation:

Foundation: Ensure a stable and level base to support the pump.

Alignment: Properly align the pump with the drive motor to prevent undue stress.

Connections: Connect the inlet and outlet pipes, ensuring they are secure and leak-free.

Electrical Hookup: For electric motor-driven pumps, connect the power supply according to the manufacturer's specifications.

Maintenance:

Regular Inspection: Check for signs of wear or damage, especially on the screw and stator.

Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction and wear.

Seal Replacement: Periodically inspect and replace seals to prevent leaks.

Cleaning: Regularly clean the pump to prevent buildup of materials that could affect performance.

Problem: Pump not starting.

Solution: Check the power supply and ensure all electrical connections are secure.

Problem: Loss of suction.

Solution: Verify that the inlet is not clogged and that the pump is primed correctly.

Problem: Excessive vibration.

Solution: Ensure the pump is properly aligned and that the foundation is stable.

Problem: Leakage.

Solution: Inspect seals and gaskets for wear and replace as necessary.

The G-Type Movable Single-Screw Pump is a reliable and efficient solution for handling challenging fluids in various industrial applications. Its robust design, combined with its ability to manage high-viscosity and abrasive materials, makes it a preferred choice for many industries. Regular maintenance and proper installation are key to ensuring optimal performance and longevity of the pump.

Copyright © Jiangsu Longjie Pump Manufacturing Co., Ltd.

This website uses cookies to ensure you get the best experience on our website.